Some renowned engineering design and fabrication workshops simplify equipment design processes and improve the accuracy and efficiency of lathe machines by skilled engineers. These professional services can boost the output of a variety of industries, including manufacturing, automotive, aerospace, and construction.

To save time and money on material and component transfers, builders and construction contractors often seek out specialists for steel fabrication in Melbourne for cut, bent and assembled steel pieces varied by their lengths and thicknesses to develop new products, machinery parts or equipment.

Advantages of Working with Skilled Engineering and Machining Business:

Recognised engineering and fabrication services on-site heavy equipment maintenance that provides precise machining and fabrication activities ahead of time necessary for various industrial projects.

Specialised parts, fittings, and components for machinery and equipment utilised in major construction projects require workshop machining and equipment repair services.

They offer on-site fabrication services encourage cooperation between many professions, enable quicker modifications and customisations, cut down on delays, and produce a more effective workflow and improved project management.

Their expertise can improve the machine and product quality by quickly evaluating and modifying parts to suit specific requirements at a fair price.

Aside from construction, other industries that need on-site or mobile lathe workshops include manufacturing, aerospace, automotive, and heavy equipment.

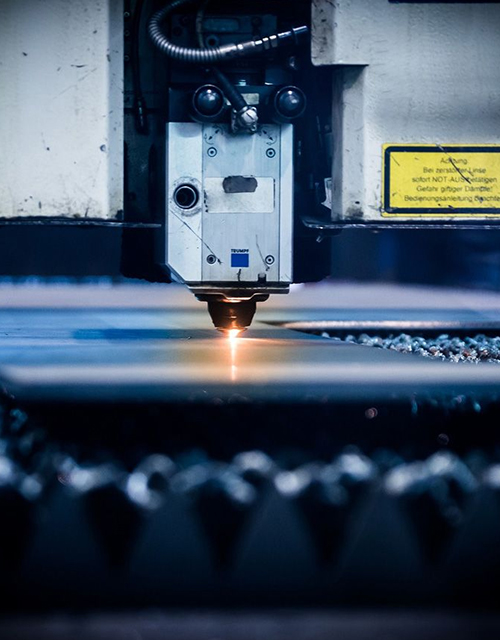

Critical components are manufactured and maintained by these companies using precise machining. To effectively manage complex projects and guarantee excellent results, a market-leading engineering and machining specialist can offer a broad range of services, such as heavy equipment repair, CNC milling, on-site welding, specialised lathe machining, CNC lathes, presses, line boring services, and robotic welders.

The functionality and safety of construction equipment depend on the prompt repair, refurbishment, or manufacturing of precise parts made possible by the use of competent engineering services.

Projects are completed on schedule and with greater efficiency thanks to their outstanding approach to ensure businesses complete their projects on scheduled time, save money and build trust in investors and customers. They have expertise with state-of-the-art technology to guarantee exceptional outcomes and on-time completion.

Meanwhile, any company that needs engineering designs, fabrication work or refurbishment of machines on-site, should get in touch with renowned engineering experts nearby.