The top on site machining companies provides a wide range of services to guarantee the effective operation of industry machinery and equipment. One such service that is essential to the smooth running of industrial machinery and is therefore highly significant to the industry is gearbox repair.

Line boring equipment is a machinery that can be worked upon by professionals working in the best machining companies. A company with substantial expertise should be chosen when it comes to machine and factory equipment engineering capabilities, such as design fabrication, machining, and engineering maintenance.

These days, a lot of industrial operations use CNC to operate machinery and industrial instruments. Because CNC machines provide excellent control, they can do tasks quickly and with extreme efficiency. This machine is utilised for turret punching, rolling, pressing, and laser cutting, among other operations. Numerous sectors need CNC machining services, therefore it's ideal to work with firms that have a lot of expertise in this area. The top businesses can provide CNC machining services for a wide range of metals, including brass, titanium, aluminium, and more.

A Summary of a Few Machining Services Provided by the Machining Companies

- On-Site and In-Situ Line Boring: This service is critical since it's needed to enlarge holes in industrial equipment across a variety of sectors. These businesses also offer additional on-site services like rotary welding, machining, and flange facing.

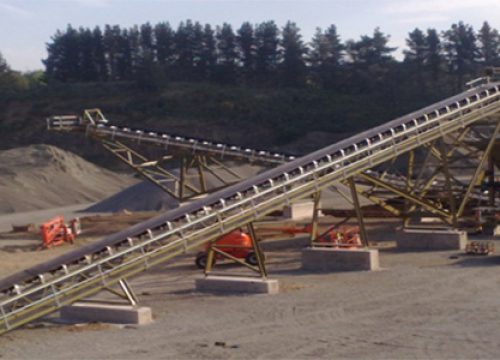

- Quarry Maintenance Services: Services including planned fixed equipment shutdown maintenance and component repairs necessitate quarry site upkeep. These services are necessary to make sure that any problems with industrial organisations are resolved quickly, which in turn increases production.

The top businesses in the fields of power generation, oil and gas processing, food processing, coal mining, sand mining, forestry, etc. should use qualified service providers for engineering design and other engineering workshop services. To arrange for their services, give the top service providers who offer these services a call and let them know what you need.