In Melbourne, milling workshops and metal fabrication services are transforming the landscape of manufacturing and construction. These facilities are not just about shaping metal; they're about crafting solutions that power industries, from automotive to architecture. The precision and innovation found in Melbourne's milling workshops and metal fabrication services underscore their critical role in today's economy.

Milling workshops in Melbourne specialize in cutting and shaping materials with unmatched precision. Using advanced CNC (Computer Numerical Control) technology, these workshops can handle complex designs and tight tolerances that manual processes cannot achieve. This capability makes them invaluable to sectors that require precise components, such as aerospace and medical devices.

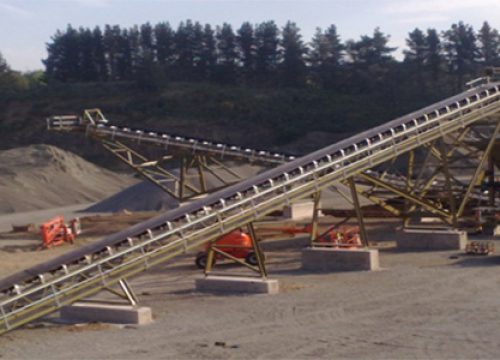

Metal fabrication in Melbourne take raw materials and transform them into finished products or parts. These services cover a wide range of processes, including welding, cutting, bending, and assembling. Fabricators work with various metals, such as steel, aluminum, and copper, offering customized solutions to meet the unique needs of each project. Whether it's constructing a building framework or creating bespoke furniture, metal fabricators in Melbourne bring visions to life with their expertise and craftsmanship.

Sustainability is also a key focus for milling workshops and metal fabricators in Melbourne. Many are adopting eco-friendly practices, such as recycling scrap metal and using energy-efficient machinery. This commitment not only reduces their environmental impact but also appeals to clients looking for sustainable manufacturing options.

Customer service stands out in Melbourne's metalworking industry. Providers work closely with clients, offering expert advice and tailored services to ensure the final product meets or exceeds expectations. This collaborative approach has built strong relationships and a reputation for excellence in the Melbourne area.

In conclusion, milling workshops and metal fabrication services in Melbourne are essential to the success of various industries. Their commitment to precision, innovation, and sustainability makes them key players in the manufacturing and construction sectors, driving progress and excellence in the region.